IK-D90/ IK-D90-L

basic information

specifications

Images

- IK-D90 & IK-D90-L (800 rpm/2000 rpm)

- 1. The deep hole milling head is a angle head designed for extending the machining stroke, providing a longer processing range.

- 2. Mostly applied in traditional gantry, CNC gantry, machining center machines, and dedicated milling machines, among others.

- 3. It uses precision grinding gears made in Taiwan, it is suitable for high-torque machining. (800 rmp).

- Commonly used in mold manufacturing, processing of plastic and steel materials, and heavy cutting of medium carbon materials.

- 4. It uses Japanese-made precision-ground gears, suitable for high-speed precision machining.(2000 rpm)

- Commonly used in mold manufacturing, aluminum processing, and light precision machining.

- 5. IK Deep Head series has two types.(IK-D90 & IK-D90-L)

- In addition to the above features, this product can be paired with the IK-N95 semi-automatic hydraulic rotary table, enabling automatic rotation for multi-angle processing (IK-D90+N95 / 90° semi-automatic right-angle milling head).

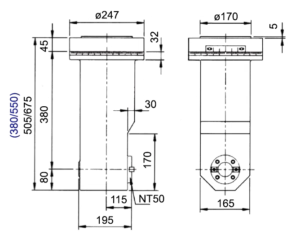

The IK-D90 and IK-D90-L deep milling heads use an NT50 spindle with a 1:1 direct-drive ratio, supporting a maximum cutter diameter of 150 mm. The IK-D90 has a maximum speed of 800 rpm and weighs approximately 98 kg, while the extended-length IK-D90-L operates at up to 2000 rpm with a weight of approximately 130 kg. Their rigid housing ensures high stability during heavy-duty side cutting. The direct-drive design preserves full spindle torque and speed. The long-body IK-D90-L is ideal for deep cavity access, angular slotting, drilling, and face milling.