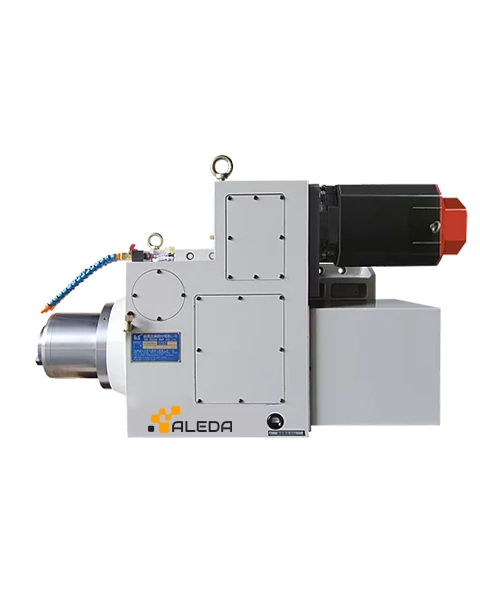

IK-H4500-A

Manufacturer:

ALEDA Techno

Country of Origin:

Taiwan

Short description:

CNC Horizontal Machining Centers Geared Head

basic information

specifications

Images

- 1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

- 2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you.

- 3. This product can be installed to a computer-controlled horizontal milling machine and a special purpose machine.

- 4. This products doesn’t include a servo motor or servo controller.

- 5. The IK CNC milling head series has three kinds of products.

The CNC Horizontal Gear Milling Head features a BT50 spindle type with a Ø200 mm housing and is designed for a recommended spindle motor of 18.5 kW (25 HP). It supports a maximum spindle speed of 4500 rpm and delivers a clamping force of 18 kN. The spindle dissipates heat at a rate of 1500 kcal/h using oil-based cooling. It utilizes a 0.61 gear ratio and is supported by an NN3018K front bearing and a 90BAR10S rear bearing. Lubrication is grease-based, with a positioning preload system. Standard accessories include the CNC Horizontal Gear Milling Head (4500 RPM / BT50), a lock knife block with lock/unlock sensor, spindle positioning sensor, splash guard, and oil pressure pipe. A spindle servo motor (18.5 kW / 25 HP) is required but not included. Buyers must supply correct motor specifications. Manufactured in Taiwan, the head weighs approximately 612 kg and includes a 1-year warranty (excluding user-induced damage).